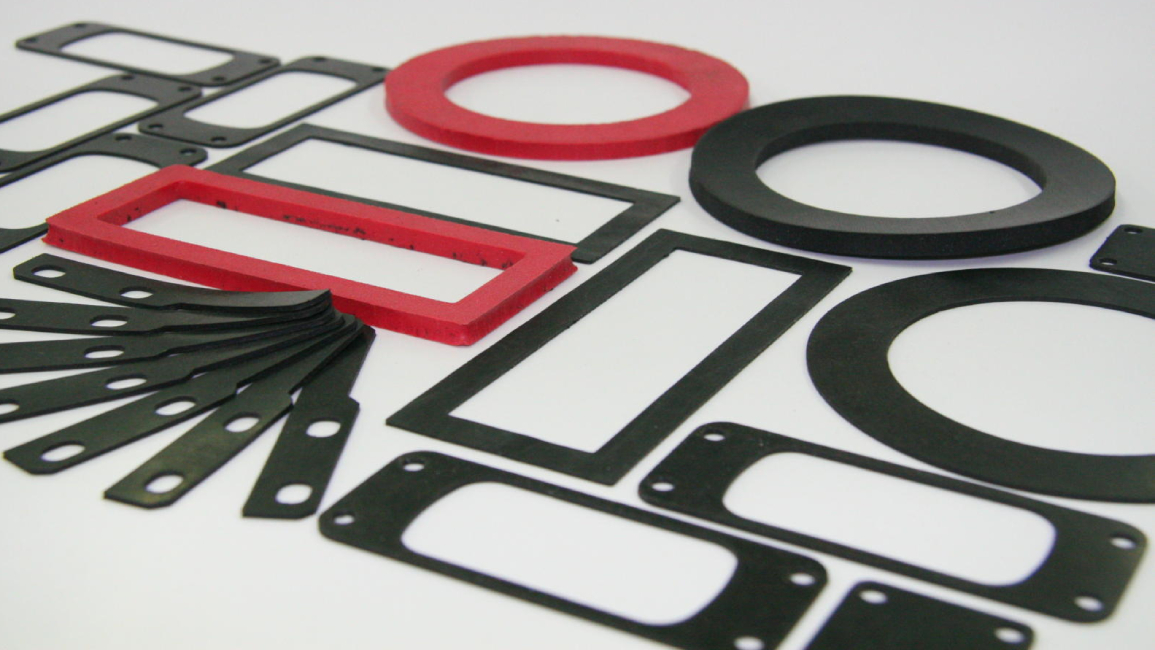

Rubber Gasket Seals: Reliable and Versatile Sealing Solutions

High-Quality Rubber Gasket Seals for Effective Sealing Performance

Rubber gasket seals are crucial components in numerous industries. Made from elastic materials like silicone or neoprene, these seals fit into spaces between two surfaces to create a tight, leak-proof connection. From automotive to manufacturing, rubber gasket seals are everywhere.

Their importance lies in the prevention of costly leaks. By creating a barrier between two surfaces, rubber gasket seals seal the connection and prevent air, chemicals, or other materials from passing through. As simple as it sounds, their design and function require some understanding. Rubber gasket seals function to create tight and secure seals between mechanical parts. They work by preventing leaks, it keeps tight and secure. By "sitting" between two surfaces, they prevent liquids or gasses from escaping or entering spaces caused by the imperfect fit of mechanical parts. Now that you know the basics, let's dive deeper into the types, applications, and maintenance of rubber gasket seals.

Types of Rubber Gasket Seals

Rubber gasket seals are utilized to seal connections so as to prevent any leakage. These seals are manufactured in different types, each designed with its own unique purpose. The O-ring seals, which are typically used in hydraulic systems, create a seal by being compressed between two surfaces. U-cup seals are used in hydraulic cylinders to prevent leakage. Cord stock seals, on the other hand, are used in applications that require a custom fit.

Each type of seal has its own distinct advantages and disadvantages, so it's important to choose the right one for your specific application. The O-ring seals, for example, are often the first choice when a water-tight seal is needed, while cord stock seals are the preferred choice when a custom-fitted seal is required. The U-cup seals are best suited for hydraulic systems, where compression of the seal is needed to fill gaps and prevent leaks. They are also popular in sealing applications where space is limited.

- Prevents leakage

- Eliminates vibration

- Protect surface from rust and external damage

- Easy fitting due to dimensional accuracy

Applications

Rubber gasket seals find applications across various industries, including automotive, construction, and manufacturing. In the automotive industry, rubber seals are used in engines and other mechanical components to prevent leakage of fluids and gases. Infact, the entire dynamic of most automobile engines relies heavily on these seals. In the construction industry, they’re used to weatherproof buildings and to join pipes. In the manufacturing industry, rubber seals are often used in machinery to ensure that fluids and gases remain contained.

Installation and Maintenance

Proper installation techniques are crucial for the successful use of rubber gasket seals. Before installation, ensure that the surface is clean and free of debris. One common mistake is to use lubricants that can damage the seal. Always use a compatible lubricant that will not harm the rubber material. During installation, take care not to over-compress the seal, as this can cause unnecessary stress leading to premature wear. If you are not sure about the appropriate compression for the specific seal type, consult the manufacturer's guidelines.

Proper maintenance practices are equally important to ensure the longevity of rubber gasket seals. Regularly inspect the seals for signs of wear and tear, such as cracks, punctures, or deformities. Replace worn-out seals immediately to prevent leaks. To extend the service life of the gasket seals, conduct regular maintenance on the equipment where they are being used. This includes cleaning the equipment, removing all debris, and ensuring that the seals are not exposed to harsh chemicals or extreme temperatures.

Advantages of Rubber Gasket Seals

Rubber gasket seals are crucial components when it comes to ensuring leakage-proof connections. These seals provide a range of advantages that make them a popular choice across various industries. One of the primary benefits of rubber gasket seals is that they significantly reduce the risk of leaks. Their design ensures a tight fit that prevents fluid or gas from escaping through the connection, thereby preventing damage to the surrounding areas.

In addition to their leak-proof properties, rubber gasket seals are also highly durable and long-lasting. With proper installation and maintenance, these seals can perform their intended function for an extended period, which translates to cost savings over time. Rubber gasket seals are also easy to install and replace, making them an attractive option for manufacturers and DIY enthusiasts alike. Unlike other types of seals, rubber gasket seals do not require any specialized tools or equipment, and the installation process is relatively straightforward.