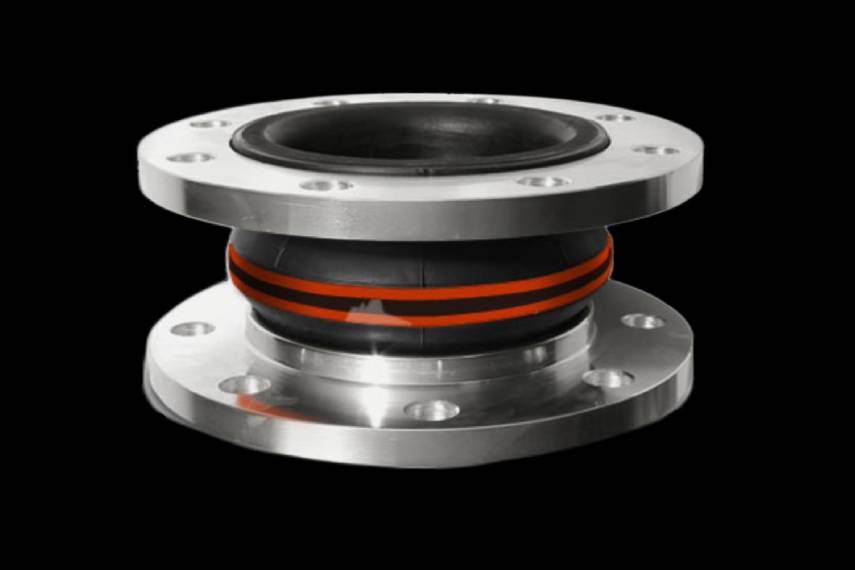

Rubber Bellows: Flexible and Protective Solutions for Various Industries

High-Quality Rubber Bellows for Reliable Protection and Flexibility

Rubber bellows might seem like a fanciful term, but it's just a fancy word for a type of expansion joint. Essentially, a rubber bellow is a flexible element made of rubber or a similar elastomer that can compress or expand in response to changes in pressure or temperature. They are often used in many industries because of their unique properties.

There are different types of rubber bellows, such as molded, convoluted, and fabric reinforced bellows. Each type has its own advantages and disadvantages, making it crucial for industries to choose the right one for their specific needs.

Applications of Rubber Bellows

Rubber Bellows are widely used across multiple industries for specific applications. One such industry that uses rubber bellows extensively is the Automotive Industry. Rubber Bellows are used in the suspension system of a vehicle as a dust cover to keep dirt and debris from damaging the suspension. They also play a crucial role in engines, transmissions, and exhaust systems.

Maintenance and Care for Rubber Bellows

- Cleaning and Lubrication

- Storage and Handling

- Replacements and Repairs

Advantages of Rubber Bellows

Rubber bellows are a popular choice across industries, thanks to their numerous advantages. Firstly, their flexibility makes them ideal for applications that require a certain amount of bendability in their components. Secondly, they have a high resistance to changes in temperature and pressure, which makes them reliable in extreme operating conditions. Durability is another key advantage, as they can withstand constant wear and tear without needing replacements. Lastly, rubber bellows can be customized to specific requirements, making them a versatile and adaptable addition to any project.

Factors to Consider while Choosing Rubber Bellows

When it comes to choosing rubber bellows, there are several factors that need to be considered to ensure that they meet your requirements. One of the most important aspects is the size and design specifications of the bellows, as it should be customized to suit your needs. This includes factors such as the size of the bellows, the type of material used, and the shape and design elements of the bellows.

Another key aspect to keep in mind is the specific application requirements of the bellows. This involves considering the environment in which it will be used, the pressure and temperature requirements, and any regulatory or safety standards that need to be met. Failure to consider these factors can result in costly mistakes and safety risks.