Site Work

On-site inspection, repair and complete relining (where applicable and suitable) of rubber lined plant.

Welcome to ASB Industries Pvt. Ltd

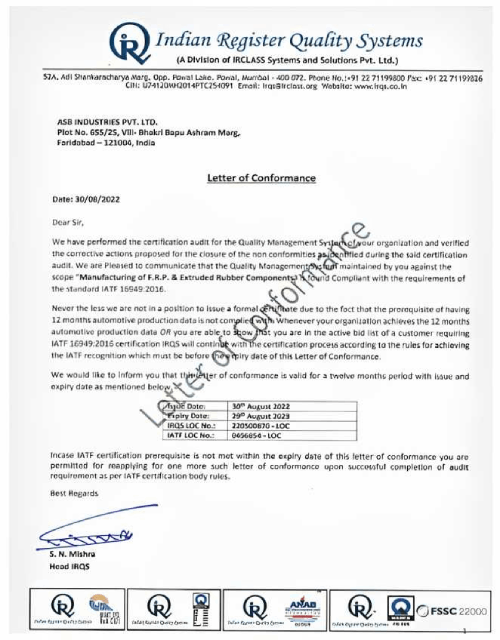

A trusted IATF 16949:2016 certified manufacturer based in Faridabad, Haryana, India since 1973. We specialize in high-quality rubber and fibre glass products that offer dimensional accuracy, ruggedness, and low maintenance. Our range includes rubber linings, seals, gaskets, and extrusion/profiles, as well as fibre reinforced plastic (FRP) linings and moulded items/components.

We provide customization options, utilize premium materials, and offer value-added services like sand/shot blasting and painting. Our products are known for their surface protection and versatility across various industrial applications. With a strong management team and industry professionals, We are committed to exceeding expectations and delivering excellence.

Abrasion resistant rubber linings for rubber lined pipes, sand washing plant, hoppers, chutes, cyclones, separators, trammels etc. Also steel backed rubber wear plates, and rubber coated conveyor rollers.

Chemical resistant rubber linings for vessels, pipes, chemical dosing tanks, valves, pumps, flow meters etc.

Chemical resistant rubber linings for tanks, process vessels, pipes, valves, pumps, filters, mixers and agitators, centrifuges, fan casings and impellors etc.

Chemical resistant rubber linings for electroplating tanks, anodising tanks, pickling tanks, filters, pipes, and effluent tanks. Also wear resistant rubber linings for rubber lined vibratory finishing machines, shot blast rooms and cabinets.

Food quality rubber linings for rubber lined hoppers, chutes, process vessels, coating pans, pipes, mixers, agitators etc.

Protective rubber coatings for grabs, hooks, clamps, and fork lift forks. Wear resistant rubber linings for hoppers, chutes, separators, storage bins etc. Rubber coatings for conveyor rollers.

Wear resistant rubber linings for rubber lined chutes, ducts, pipes and hoppers. Chemical resistant rubber linings for rubber lined treatment tanks and holding tanks.

Corrosion resistant rubber linings for rubber lined cooling pipe work and fume scrubbers, wear resistant linings for dredging pipe work and cable pulleys.

Corrosion resistant rubber linings for rubber lined water treatment plant, chemical storage tanks, and cooling pipe work. Wear resistant rubber linings for coal handling and ash recovery plant, coatings for conveyor rollers etc.

Wear and abrasion resistant rubber coatings for road rollers, compaction plates, and rubber linings for cement mixers and chutes.

Our wide range of sought-after products and services caters to the demanding needs of the automotive industry.

We provide cutting-edge products and services tailored to the glass industry's specific requirements.

We excels in rubber extrusion, providing precise profiles for diverse applications with superior quality and support(-40°C to 120°C).

Superior rubber solutions: flux for adhesion, bushings for vibration isolation, and O-rings for leak prevention. Trust us for quality rubber products.

We provides superior rubber lining solutions for enhanced protection against abrasion, corrosion, and chemicals.

We provides FRP linings for tanks and vessels, along with customized moulded items for automotive and railways.

We prioritize reliability in everything we do. With over five decades of experience in the industry, we have established a strong track record of delivering high-quality products and solutions.

Quality is at the core of our operations. We adhere to stringent quality control measures throughout the manufacturing process to ensure that our products meet the highest standards.

Our industry expertise and skilled professionals. With deep knowledge in rubber and FRP, we deliver cutting-edge solutions by staying updated with the latest trends, technologies, and best practices.

ASB Industries Pvt. Ltd. provides a comprehensive range of FRP linings, including tank, vessel, epoxy, and chemical resistant linings. We also offer customized FRP molded items for automotive/railway parts and more. Our linings have diverse applications, from leak-proofing rooftops to anti-corrosion treatment for metal tanks. Customization options are available in various sizes, finishes, and designs.

Rubber extrusion & moulding is a versatile process used to create a wide range of rubber profiles with varying shapes and dimensions. At ASB Industries Pvt. Ltd., we specialize in rubber extrusion, offering high-quality products tailored to meet our customers' specific requirements.

ASB Industries Pvt. Ltd. offers superior rubber lining solutions for enhanced protection against abrasion, corrosion, and chemicals. With customized solutions, expertise, versatility, and cost-effectiveness, we ensure reliable and long-lasting results.

On-site inspection, repair and complete relining (where applicable and suitable) of rubber lined plant.

Inspection and advice regarding the condition / maintenance / replacement of existing rubber lined plant.

Collection and delivery of customers’ equipment

In-house blast cleaning of metal fabrications; castings; architectural steelworks; vehicle; machinery components